Please enter the website title

Products

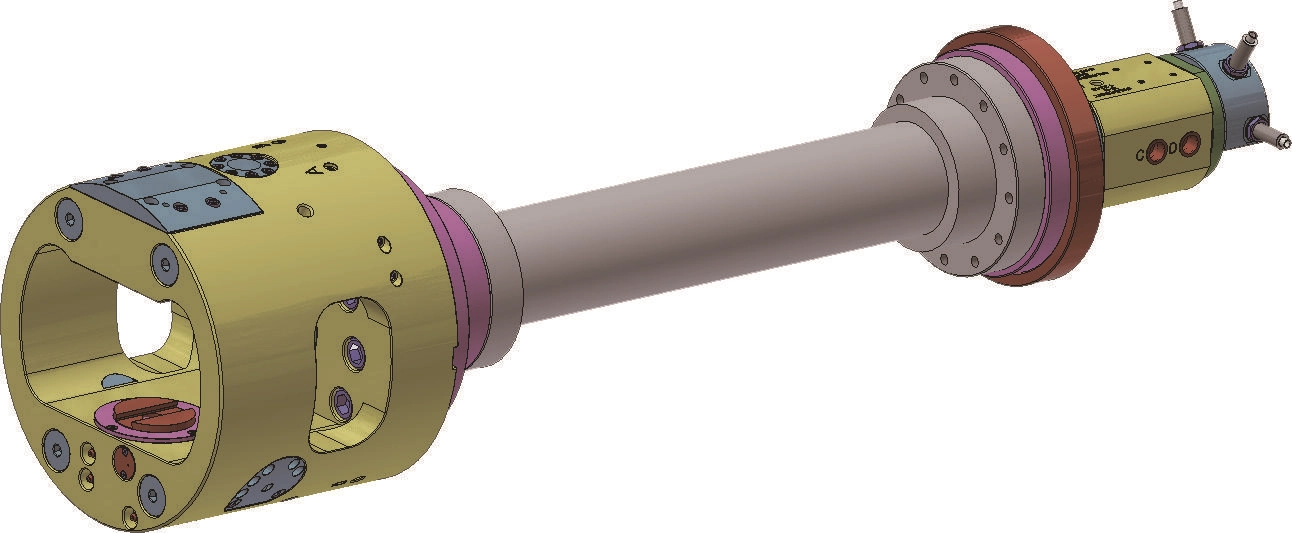

IC,TB-IC Indexing Chucks, Hydraulic Feed Tube

Hangzhou Chandox Tosun Import & Export company is a joint venture enterprise, it was built in 2005 and located in city of Hangzhou. It is a Chandox sales company in Mainland, We have certificated ISO9001-2015 quality and management system. We have over forty professional employees to serve our customers, we also have four sales offices located in Shenyang, Yantai, Chongqing and Donguan.

Product Details

1.Specialize for multi-axis manufacturing requirement, ex: Valve, Cross bearing, hose joint..etc.

2.Automatic mechanism: With the special hydraulic feeder and automatic control unit, the chuck could 90 indexing automatically during the spindle turning.

3.Centrifugal force compensation: Compensation structure could reduce the clamping force lost during high speed turning and stabilize the work-clamping.

4.The optimal structure design provides the best rigidity and precision.

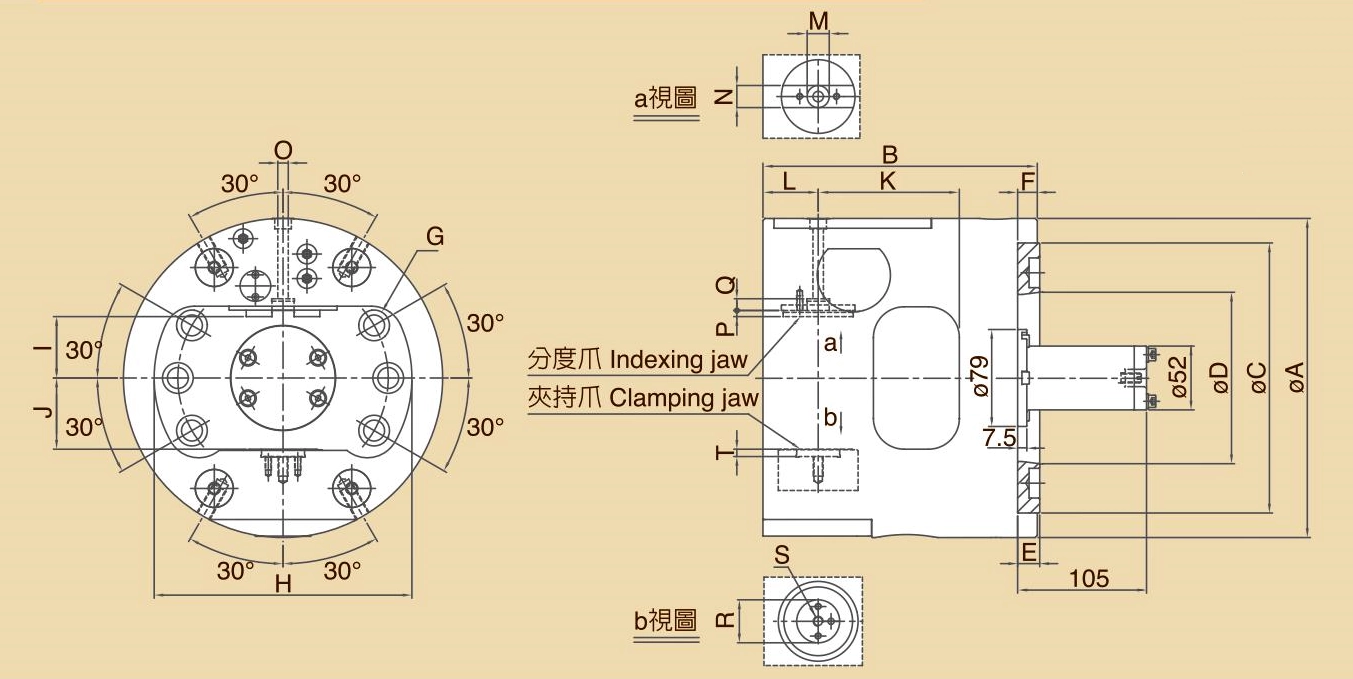

| MODEL /SPEC. | A | B | C | D | E | F | G | H | I |

| IC-260 | 260 | 223.5 | 220 | 139.719 | 18 | 16 | 6-M16x2P(PCDφ171.4) | 210 | 50 |

| MODEL /SPEC. | J max. | J min. | K | L | M | N | O | P | Q |

| IC-260 | 58 | 40 | 115 | 45 | 18 | 18 | 8.5 | 5 | 9.55 |

| MODEL /SPEC. | S | φR | T | Index Angle | Piston Area (cm²) | Plunger Stroke (mm) | |||

| IC-260 | M8x1.25P | 35 | 6 | 4x90° | 43 | 18 | |||

| MODEL /SPEC. | Max. Hydr Pressure Kgf/cm² (MPa) | Max. Speed r.p.m (min⁻¹) | Max. Gripping Force kgf (kN) | Matching Hydraulic feed tube | Gripping Range | ||||

| Max. rotation dia | Thickness | ||||||||

| IC-260 | 51 | 4.9 | 3600 | 2000 | 19.6 | TB-IC | 200 | 70 | |

★ Reserve the right to modify spcifications

choose an area code